ABSTRACT

Acoustic emission technique (AET) has been extensively researched and

found to be one of the most of the promising techniques for condition

monitoring of machine tools. AE is non-intrusive, simple in operation and gives

fast dynamic response.

Acoustic Emission

Technique (AET) is relatively recent entry in the field of NDE which has

particularly shown a very high potential for material characterization and

damage assessment in conventional as well as non – conventional materials. Due

to its complementary non – destructive evaluation methods, it is utilized for a

wide range of applications.

Acoustic Emission (AE) is defined as the

class of phenomenon where transient elastic waves are generated by the rapid

release of energy from localized sources within a material, or the transient

elastic waves so generated. In other words, AE refers to the stress waves

generated by dynamic processes in materials. Emission occurs as a release of a

series of short impulsive energy packets. The energy thus released travels as a

spherical wave front and can be picked from the surface of a material using

highly sensitive transducers, (usually electro mechanical type).

This paper

discusses the applicability of AET for monitoring defects in

materials,structures,etc while in operation. This prevents sudden failure of a

machine tool,material or a structure.

INTRODUCTION TO ACOUSTICS.

Acoustics is the interdisciplinary science that

deals with the study of sound, ultrasound and infrasound (all mechanical waves in gases, liquids, and solids). A scientist

who works in the field of acoustics is an acoustician. The application of acoustics in technology is called acoustical engineering.

The science of acoustics spreads across so

many facets of our society—music, medicine, architecture, industrial

production, warfare and more. Art, craft, science and technology have provoked

one another to advance the whole, as in many other fields of knowledge.

The word

"acoustic" is derived from the Greek word (akoustikos), meaning "for hearing” or “ready to

hear".

The study of acoustics revolves around the

generation, propagation and reception of mechanical waves and vibrations.

The major subfields of

acoustics are classified below,

PHYSICAL ACOUSTICS

|

BIOLOGICAL ACOUSTICS

|

ACOUSTICAL ENGINEERING

|

|

|

|

INTRODUCTION TO ACOUSTIC EMISSION TESTING

Acoustic

Emission (AE) refers to the generation of transient elastic waves produced by a

sudden redistribution of stress in a material. When a structure is subjected to

an external stimulus (change in pressure, load, or temperature), localized

sources trigger the release of energy, in the form of stress waves, which

propagate to the surface and are recorded by sensors. With the right equipment

and setup, motions on the order of picometers (10 -12 m) can be identified.

Sources of AE vary from natural events like earthquakes and rockbursts to the

initiation and growth of cracks, slip and dislocation movements, melting,

twinning, and phase transformations in metals. In composites, matrix cracking

and fiber breakage and debonding contribute to acoustic emissions. AE’s have

also been measured and recorded in polymers, wood, and concrete, among other

materials.

Detection and

analysis of AE signals can supply valuable information regarding the origin and

importance of a discontinuity in a material. Because of the versatility of

Acoustic Emission Testing (AET), it has many industrial applications (e.g.

assessing structural integrity, detecting flaws, testing for leaks, or

monitoring weld quality) and is used extensively as a research tool.

Acoustic Emission

is unlike most other nondestructive testing (NDT) techniques in two regards.

The first difference pertains to the origin of the signal. Instead of supplying

energy to the object under examination, AET simply listens for the energy

released by the object. AE tests are often performed on structures while in

operation, as this provides adequate loading for propagating defects and

triggering acoustic emissions.

The second

difference is that AET deals with dynamic processes, or changes, in a material.

This is particularly meaningful because only active features (e.g. crack

growth) are highlighted. The ability to discern between developing and stagnant

defects is significant. However, it is possible for flaws to go undetected

altogether if the loading is not high enough to cause an acoustic event.

Furthermore, AE testing usually provides an immediate indication relating to

the strength or risk of failure of a component. Other advantages of AET include

fast and complete volumetric inspection using multiple sensors, permanent

sensor mounting for process control, and no need to disassemble and clean a

specimen.

Unfortunately,

AE systems can only qualitatively gauge how much damage is contained in a

structure. In order to obtain quantitative results about size, depth, and

overall acceptability of a part, other NDT methods (often ultrasonic testing)

are necessary. Another drawback of AE stems from loud service environments

which contribute extraneous noise to the signals. For successful applications,

signal discrimination and noise reduction are crucial.

THEORY

- AE SOURCES

As mentioned in the

Introduction, acoustic emissions can result from the initiation and growth of

cracks, slip and dislocation movements, twinning, or phase transformations in

metals. In any case, AE’s originate with stress. When a stress is exerted on a

material, a strain in induced in the material as well. Depending on the

magnitude of the stress and the properties of the material, an object may

return to its original dimensions or be permanently deformed after the stress

is removed. These two conditions are known as elastic and plastic deformation,

respectively.

The most detectible

acoustic emissions take place when a loaded material undergoes plastic

deformation or when a material is loaded at or near its yield stress. On the

microscopic level, as plastic deformation occurs, atomic planes slip past each

other through the movement of dislocations. These atomic-scale deformations

release energy in the form of elastic waves which “can be thought of as

naturally generated ultrasound” traveling through the object. When cracks exist

in a metal, the stress levels present in front of the crack tip can be several

times higher than the surrounding area. Therefore, AE activity will also be

observed when the material ahead of the crack tip undergoes plastic deformation

(micro-yielding).

Two sources of fatigue

cracks also cause AE’s. The first source is emissive particles (e.g.

nonmetallic inclusions) at the origin of the crack tip. Since these particles

are less ductile than the surrounding material, they tend to break more easily

when the metal is strained, resulting in an AE signal. The second source is the

propagation of the crack tip that occurs through the movement of dislocations

and small-scale cleavage produced by triaxial stresses.

The amount of energy

released by an acoustic emission and the amplitude of the waveform are related

to the magnitude and velocity of the source event. The amplitude of the

emission is proportional to the velocity of crack propagation and the amount of

surface area created. Large, discrete crack jumps will produce larger AE

signals than cracks that propagate slowly over the same distance.

Detection and

conversion of these elastic waves to electrical signals is the basis of AE testing.

Analysis of these signals yield valuable information regarding the origin and

importance of a discontinuity in a material. As discussed in the following

section, specialized equipment is necessary to detect the wave energy and

decipher which signals are meaningful.

THEORY

- ACOUSTIC WAVES

WAVE

PROPAGATION

A primitive wave released at the AE source is

illustrated in the figure right. The displacement waveform is a step-like

function corresponding to the permanent change associated with the source

process. The analogous velocity and stress waveforms are essentially

pulse-like. The width and height of the primitive pulse depend on the dynamics

of the source process. Source processes such as microscopic crack jumps and

precipitate fractures are usually completed in a fraction of a microsecond or a

few microseconds, which explains why the pulse is short in duration. The

amplitude and energy of the primitive pulse vary over an enormous range from

submicroscopic dislocation movements to gross crack jumps.

Waves radiates from the

source in all directions, often having a strong directionality depending on the

nature of the source process, as shown in the second figure. Rapid movement is

necessary if a sizeable amount of the elastic energy liberated during

deformation is to appear as an acoustic emission.

As these primitive

waves travel through a material, their form is changed considerably. Elastic

wave source and elastic wave motion theories are being investigated to

determine the complicated relationship between the AE source pulse and the

corresponding movement at the detection site. The ultimate goal of studies of

the interaction between elastic waves and material structure is to accurately

develop a description of the source event from the output signal of a distant

sensor.

However, most

materials-oriented researchers and NDT inspectors are not concerned with the

intricate knowledge of each source event. Instead, they are primarily

interested in the broader, statistical aspects of AE. Because of this, they

prefer to use narrow band (resonant) sensors which detect only a small portion

of the broadband of frequencies emitted by an AE. These sensors are capable of

measuring hundreds of signals each second, in contrast to the more expensive

high-fidelity sensors used in source function analysis. More information on

sensors will be discussed later in the Equipment section.

The signal that is

detected by a sensor is a combination of many parts of the waveform initially

emitted. Acoustic emission source motion is completed in a few millionths of a

second. As the AE leaves the source, the waveform travels in a spherically

spreading pattern and is reflected off the boundaries of the object. Signals

that are in phase with each other as they reach the sensor produce constructive

interference which usually results in the highest peak of the waveform being

detected. The typical time interval from when an AE wave reflects around the

test piece (repeatedly exciting the sensor) until it decays, ranges from the

order of 100 microseconds in a highly damped, nonmetallic material to tens of

milliseconds in a lightly damped metallic material.

ATTENUATION

The

intensity of an AE signal detected by a sensor is considerably lower than the

intensity that would have been observed in the close proximity of the source.

This is due to attenuation. There are three main causes of attenuation,

beginning with geometric spreading. As an AE spreads from its source in a

plate-like material, its amplitude decays by 30% every time it doubles its

distance from the source. In three-dimensional structures, the signal decays on

the order of 50%. This can be traced back to the simple conservation of energy.

Another cause of attenuation is material damping, as alluded to in the previous

paragraph. While an AE wave passes through a material, its elastic and kinetic

energies are absorbed and converted into heat. The third cause of attenuation

is wave scattering. Geometric discontinuities (e.g. twin boundaries,

nonmetallic inclusions, or grain boundaries) and structural boundaries both

reflect some of the wave energy that was initially transmitted.

Measurements of the

effects of attenuation on an AE signal can be performed with a simple apparatus

known as a Hsu-Nielson Source. This consists of a mechanical pencil with either

0.3 or 0.5 mm 2H lead that is passed through a cone-shaped Teflon shoe designed

to place the lead in contact with the surface of a material at a 30 degree

angle. When the pencil lead is pressed and broken against the material, it

creates a small, local deformation that is relieved in the form of a stress

wave, similar to the type of AE signal produced by a crack. By using this

method, simulated AE sources can be created at various sites on a structure to

determine the optimal position for the placement of sensors and to ensure that

all areas of interest are within the detection range of the sensor or sensors.

WAVE

MODE AND VELOCITY

As mentioned earlier, using AE inspection in conjunction with

other NDE techniques can be an effective method in gauging the location and

nature of defects. Since source locations are determined by the time required

for the wave to travel through the material to a sensor, it is important that

the velocity of the propagating waves be accurately calculated. This is not an

easy task since wave propagation depends on the material in question and the

wave mode being detected. For many applications, Lamb waves are of primary

concern because they are able to give the best indication of wave propagation

from a source whose distance from the sensor is larger than the thickness of

the material. For additional information on Lamb waves, see the wave mode page

in the Ultrasonic Inspection section.

AE BARKHAUSEN TECHNIQUES

BARKHAUSEN

EFFECT

The Barkhausen

effect refers to the sudden change in size of ferromagnetic domains that occur

during magnetization or demagnetization. During magnetization, favorably

oriented domains develop at the cost of less favorably oriented domains. These

two factors result in minute jumps of magnetization when a ferromagnetic sample

(e.g. iron) is exposed to an increasing magnetic field (see figure). Domain

wall motion itself is determined by many factors like microstructure, grain

boundaries, inclusions, and stress and strain. By the same token, the

Barkhausen effect is too a function of stress and strain.

BARKHAUSEN

NOISE

Barkhausen noise

can be heard if a coil of wire is wrapped around the sample undergoing

magnetization. Abrupt movements in the magnetic field produce spiking current

pulses in the coil. When amplified, the clicks can be compared to Rice Krispies

or the crumbling a candy wrapper. The amount of Barkhausen noise is influenced

by material imperfections and dislocations and is likewise dependent on the

mechanical properties of a material. Currently, materials exposed to high

energy particles (nuclear reactors) or cyclic mechanical stresses (pipelines)

are available for nondestructive evaluation using Barkhausen noise, one of the

many branches of AE testing.

APPLICATIONS

Acoustic

emission is a very versatile, non-invasive way to gather information about a

material or structure. Acoustic Emission testing (AET) is be applied to

inspect and monitor pipelines, pressure vessels, storage tanks, bridges, aircraft,

and bucket trucks, and a variety of composite and ceramic components. It is

also used in process control applications such as monitoring welding processes.

A few examples of AET applications follow.

WELD

MONITORING

During the welding

process, temperature changes induce stresses between the weld and the base

metal. These stresses are often relieved by heat treating the weld.

However, in some cases tempering the weld is not possible and minor cracking

occurs. Amazingly, cracking can continue for up to 10 days after the weld has

been completed. Using stainless steel welds with known inclusions and

accelerometers for detection purposes and background noise monitoring, it was

found by W. D. Jolly (1969) that low level signals and more sizeable bursts

were related to the growth of microfissures and larger cracks respectively.

ASTM E 749-96 is a standard practice of AE monitoring of continuous welding.

BUCKET

TRUCK (CHERRY PICKERS) INTEGRITY EVALUATION

Accidents,

overloads and fatigue can all occur when operating bucket trucks or other

aerial equipment. If a mechanical or structural defect is ignored, serious

injury or fatality can result. In 1976, the Georgia Power Company pioneered the

aerial manlift device inspection. Testing by independent labs and electrical

utilities followed. Although originally intended to examine only the boom

sections, the method is now used for inspecting the pedestal, pins, and various

other components. Normally, the AE tests are second in a chain of inspections

which start with visual checks. If necessary, follow-up tests take the form of

magnetic particle, dye penetrant, or ultrasonic inspections. Experienced

personnel can perform five to ten tests per day, saving valuable time and money

along the way. ASTM F914 governs the procedures for examining insulated aerial

personnel devices.

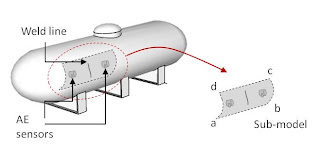

GAS TRAILER TUBES

Acoustic

emission testing on pressurized jumbo tube trailers was authorized by the

Department of Transportation in 1983. Instead of using hydrostatic retesting,

where tubes must be removed from service and disassembled, AET allows for in

situ testing. A 10% over-pressurization is performed at a normal filling

station with AE sensors attached to the tubes at each end. A multichannel

acoustic system is used to detection and mapped source locations. Suspect

locations are further evaluated using ultrasonic inspection, and when defects

are confirmed the tube is removed from use. AET can detect subcritical

flaws whereas hydrostatic testing cannot detect cracks until they cause rupture

of the tube. Because of the high stresses in the circumferential direction of

the tubes, tests are geared toward finding longitudinal fatigue cracks.

BRIDGES

Bridges contain

many welds, joints and connections, and a combination of load and environmental

factors heavily influence damage mechanisms such as fatigue cracking and metal

thinning due to corrosion. Bridges receive a visual inspection about

every two years and when damage is detected, the bridge is either shut down,

its weight capacity is lowered, or it is singled out for more frequent

monitoring. Acoustic Emission is increasingly being used for bridge

monitoring applications because it can continuously gather data and detect

changes that may be due to damage without requiring lane closures or bridge

shutdown. In fact, traffic flow is commonly used to load or stress the bridge

for the AE testing.

AEROSPACE

STRUCTURES

Most aerospace structures consist of complex

assemblies of components that have been design to carry significant loads while

being as light as possible. This combination of requirements leads to

many parts that can tolerate only a minor amount of damage before failing.

This fact makes detection of damage extremely important but components are

often packed tightly together making access for inspections difficult.

AET has found applications in monitoring the health of aerospace structures

because sensors can be attached in easily accessed areas that are remotely

located from damage prone sites. AET has been used in laboratory

structural tests, as well as in flight test applications. NASA's Wing

Leading Edge Impact Detection System is partially based on AE technology.

The image to the right shows a technician applying AE transducers on the inside

of the Space Shuttle Discovery wing structure. The impact detection

system was developed to alert NASA officials to events such as the

sprayed-on-foam insulation impact that damaged the Space Shuttle Columbia's

wing leading edge during launch and lead to its breakup on reentry to the

Earth's atmosphere.

The following research material gives details of few

applications of acoustic emission technique.

APPLICATION IN MATERIAL RESEARCH

Acoustic emission technique finds one of its largest application

fields in material research. Examples are the detection of the point of damage

initiation and the rate of damage evolution under mechanical loading (tensile,

bending, fatigue, creep),the study of phase transformation, detection of

coating wear, etc.

The emitted stress waves can be detected

by coupling piezo-electric sensors to the structure or material under study. By

analyzing the quantity and properties of acoustic emission signals information

is obtained about the processes that are active in the material under study.

Generally acoustic emission technique can

be used to obtain information of the microstructural changes that are occurring

in any loaded material.

APPLICATION IN STRUCTURAL INTEGRITY MONITORING.

The main area where the acoustic emission

technique has found practical, industrial applications is in the field of

structural integrity monitoring. By equipping a loaded, safety critical

structure with a number of piezo electric sensors, information can be gathered

about the evolution of damage in the structure during its service life.

Nowadays, wireless acoustic emission sensor networks are used for structural

health monitoring in civil engineering.

CONCLUSION

Because the physical process of acoustic emission occurs in a wide

variety of materials and under a large range of loading conditions, the

technique offers great potential for use as a continuous monitoring technique.

Due to its inherent advantages as compared to other techniques, it should

always be preferred when continuous detection is required.

No comments:

Post a Comment

leave your opinion