ABSTRACT

In the present paper, efforts have

been made to highlight the concept of an “INTELLIGENT

COOLING SYSTEM”. The basic principle behind this is to control the flow

rate of coolant by regulating the valve by implementing FUZZY LOGIC.

In

conventional process the flow rate is constant over the entire engine jacket.

Which induces thermal stresses & reduction in efficiency.

The “INTELLIGENT COOLING SYSTEM” i.e implementation of fuzzy logic will

overcome the above stated drawbacks in any crisp situation. The flow rate of

coolant will be controlled by control unit & intelligent sensors.

INTRODUCTION

The

name “INTELLIGENT COOLING SYSTEM”

represents the improved function of cooling systems. We have given this name

because in this system the sensor will sense the cylinder temperature as

similar as thermostat and will control the opening and closing of water passage

in the piston cylinder arrangement. The mass flow rate of water will be

controlled by a valve arrangement.

For regulating flow rate, a separate

programming can be done. In this programming, the piston will be considered as

an object and a relation of “temperature = water” can be used for the above

purpose.

Our system will work on the same

principle of an “INTELLIGENT CARBURETOR”

In which its aim is to supply the correct O/P i.e. air fuel mixture by sensing

the I/P i.e. operating conditions.

But, the system which attracted the

most is the “IDLE SPEED CONTROLLER” which is used to control the idle speed of

SI engine.

Conventional

Cooling system

The

following are the two main characteristics desired of an efficient cooling system

1)

It should be capable of removing

about 30% of heat generated in the combustion chamber while maintaining the

optimum temperature of the engine under all operating conditions of the

engines.

2)

It should remove heat at a faster rate when

engine is hot. However, during starting of the engine cooling should be

minimum, so that the working parts of the engine reach their operating

temperature in a short time.

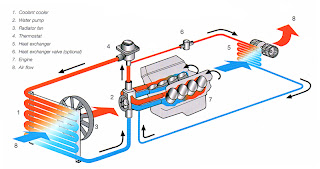

a) Liquid Cooled Systems

In

this system mainly water is used and made to circulate through the jacket

provided around the cylinder, cylinder-head, valve ports and seats where it

extracts most of the heat. The diagrammatic sketch of water circulating passage

is shown in

b) Variation of

gas temperature

There

is an appreciable variation in the temperature of the gases inside the engine

cylinder during different processes of the cycle. Temperature inside the engine

cylinder is almost the lowest at the end of suction stroke. During combustion

there is a rapid rise in temperature to a peak value which again drops during

the expansion. This variation of gas temperature is illustrated in fig (2). for

various processes in the cycle.

The cooling

system comprises of the following parts namely:

·

Radiator,

·

Thermostat,

·

Water pump &

·

Piston-cylinder assembly.

EFFECT

OF OVERHEATING :

·

Evaporation of lubricating oil that

lubricates the piston and cylinder wall. This will result in metal to metal

contact of the piston and the cylinder wall leading to piston scuffing and

piston seizure.

·

Setting up of the thermal stresses

in the cylinder, cylinder head and piston. This may lead to cracking of them.

·

Burning of the piston crown.

·

Sticking of piston rings in the

ring grooves, due to carbonization of the oil. Ring sticking will result in

inefficient sealing of the cylinder increased blow by of gases and loss of

thermal efficiency.

·

Reduction in volumetric efficiency

i.e. reduced weight of charge retained in the cylinder.

EFFECT

OF EXCESSIVE COOLING :

·

Reduction in thermal efficiency

·

Increased corrosion of engine

parts.

·

Reduced mechanical efficiency.

·

Improper vaporization of the fuel.

Also due to the inadequate supply of

the coolant the machine parts get overheated and this may lead to two effects:

·

Generation of excessive heat which

results in the break down of the engine.

·

Evaporation of the coolant (water)

may results in SCALE formation.

Effect

of high temperature on lubricating oil consumption :

High

speed produces high temperature this in turn, lowers the viscosity of the oil.

Now it can more readily work past the piston rings into the combustion chamber,

where it is burnt. Due to more temperature more oil gets into the combustion

chamber, where it burns and fouls spark-plugs, valves, rings and pistons.

Carbon formation worsens the condition since it further reduces the

effectiveness of the oil rings. The burning of oil in the combustion chamber

usually produces blue smoke from the tail pipe.

It should be remembered that abstraction of heat from the working medium by way of cooling

the engine components is a direct thermodynamic loss.

IMPLEMENTATION OF FUZZY LOGIC

To control the idle speed of spark ignition engine,

there are two possibilities. The first one is spark advancer and the second is

volumetric control of air.

In spark advancer if revolution

decreases then an advance spark increases the torque and vice versa.

In

second method if there is reduction in number of revolution, the auxiliary air

regulator increases the by-pass cross-section which increases the air flow and

vice versa.

Fuzzy in

cooling system :

Consider

the engine jacket as shown in figure 5

above which shows the sensors, valve, cylinder & an intermediate jacket, in

which sensors and valve are connected to control unit.

This control unit will not work

unless the temperature of the engine reaches to 700 C. When it

reaches to 700C or beyond it the flow will start. It begins with

maximum at middle two cylinder and less at first and last cylinders. This

change in flow rate will minimize the temperature difference between the middle

and the end cylinders. Due to this the thermal stresses get reduce and the

optimum temperature will be maintained wear will not take place.

If the temperature of the engine

cylinders increases, the sensor will sense the temperature and the signal is

given to the control unit and it controls the valve opening resulting in increase

in the flow rate. Similarly when the engine retards the temperature of the

cylinder decreases which will be sensed by the sensor and will operate the

valve.

ADVANTAGES OF INTELLIGENT COOLING SYSTEM

1) It will try to maintain the cylinder temperature

within the certain limit so that lubricating oil should not evaporate and hence

will prevent metal to metal contact.

2) It

will help to reduce the thermal stresses and hence cracking of piston cylinder.

3) Thermal

efficiency will improve.

4) It

will prevent the carbonization of oil since dealing with the optimum

temperature.

5) It

will prevent the corrosion of engine parts.

6) Mechanical

efficiency will improve.

7) Proper

vaporization of fuel will take place.

8) Excessive

cooling results in increased viscosity of lubricant oil and hence more friction

and will consume more fuel to overcome

the friction and hence results in decrease thermal efficiency. So, our system

will prevent the above factors.

9) During

starting, the engine takes some time to reach it's operating temperature and

hence it requires less or no coolant to be circulated around if so that it can

reach operating temperature easily.

10) Although

initial cost will be more but running cost will be less.

11) Less

maintenance will require.

Conclusion

We

have proposed an approach to implement fuzzy logic in an "Intelligent

Cooling System". Possible implementation

of the system and an approach is discussed along with its possible

advantages. The use of such system will solve the problems of technology

acceptance in India

Scope for

future work would concentrate on type of sensor's, valve opening mechanisms and

different coolants.

No comments:

Post a Comment

leave your opinion