INTRODUCTION

Interestingly,

using the word “turbine” to describe Tesla’s invention seems a bit misleading.

That’s because most people think of a turbine as a shaft with blades — like fan

blades — attached to it. In fact, Webster’s dictionary defines a turbine as an

engine turned by the force of gas or water on fan blades. But the Tesla turbine

doesn’t have any blades. It has a series of closely packed parallel disks

attached to a shaft and arranged within a sealed chamber. When a fluid is

allowed to enter the chamber and pass between the disks, the disks turn, which

in turn rotates the shaft. This rotary motion can be used in a variety of ways,

from powering pumps, blowers and compressors to running cars and airplanes. In

fact, Tesla claimed that the turbine was the most efficient and the most simply

designed rotary engine ever designed.

Tesla’s

new engine was a bladeless turbine, which would still use a fluid as the vehicle

of energy, but would be much more efficient in converting the fluid energy into

motion

MAIN

PARTS OF TESLA’S TURBINE

The

Rotor

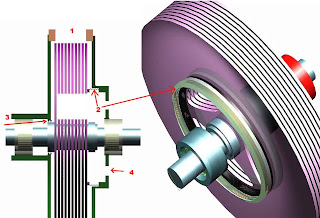

In a traditional turbine, the rotor is a shaft with blades attached. The Tesla turbine does away with the blades and uses a series of disks instead. The size and number of the disks can vary based on factors related to a particular application. It contain a “plurality” of disks with a “suitable diameter.”

In a traditional turbine, the rotor is a shaft with blades attached. The Tesla turbine does away with the blades and uses a series of disks instead. The size and number of the disks can vary based on factors related to a particular application. It contain a “plurality” of disks with a “suitable diameter.”

Each

disk is made with openings surrounding the shaft. These openings act as exhaust

ports through which the fluid exits. To make sure the fluid can pass freely

between the disks, metal washers are used as dividers. Again, the thickness of

a washer is not rigidly set, although the intervening spaces typically don’t

exceed 2 to 3 millimeters.

A

threaded nut holds the disks in position on the shaft, the final piece of the

rotor assembly. Because the disks are keyed to the shaft, their rotation is

transferred to the shaft.

The

Stator

The rotor assembly is housed within a cylindrical stator, or the stationary part of the turbine. To accommodate the rotor, the diameter of the cylinder’s interior chamber must be slightly larger than the rotor disks themselves. Each end of the stator contains a bearing for the shaft. The stator also contains one or two inlets, into which nozzles are inserted. Tesla’s original design called for two inlets, which allowed the turbine to run either clockwise or counterclockwise.

The rotor assembly is housed within a cylindrical stator, or the stationary part of the turbine. To accommodate the rotor, the diameter of the cylinder’s interior chamber must be slightly larger than the rotor disks themselves. Each end of the stator contains a bearing for the shaft. The stator also contains one or two inlets, into which nozzles are inserted. Tesla’s original design called for two inlets, which allowed the turbine to run either clockwise or counterclockwise.

This

is the basic design. To make the turbine run, a high-pressure fluid enters the

nozzles at the stator inlets. The fluid passes between the rotor disks and

causes the rotor to spin. Eventually, the fluid exits through the exhaust ports

in the center of the turbine.

One

of the great things about Tesla turbine is its simplicity. It can be built with

readily available materials, and the spacing between disks doesn’t have to be

precisely controlled. It’s so easy to build, in fact, that several mainstream

magazines have included complete assembly instructions using household

materials.

Tesla’s Turbine Operation

You

might wonder how the energy of a fluid can cause a metal disk to spin. After

all, if a disk is perfectly smooth and has no blades, vanes or buckets to

“catch” the fluid, logic suggests that the fluid will simply flow over the

disk, leaving the disk motionless. This, of course, is not what happens. Not

only does the rotor of a Tesla turbine spin — it spins rapidly.

The

reason why can be found in two fundamental properties of all fluids: Adhesion and Viscosity.

Adhesion is the tendency of dissimilar molecules to cling together due to

attractive forces. Viscosity is the resistance of a substance to flow. These

two properties work together in the Tesla turbine to transfer energy from the

fluid to the rotor or vice versa. Here’s how:

·

As the fluid moves past each

disk, adhesive forces cause the fluid molecules just above the metal surface to

slow down and stick.

·

The molecules just above

those at the surface slow down when they collide with the molecules sticking to

the surface.

·

These molecules in turn slow

down the flow just above them.

·

The farther one moves away

from the surface, the fewer the collisions affected by the object surface.

·

At the same time, viscous

forces cause the molecules of the fluid to resist separation.

·

This generates a pulling

force that is transmitted to the disk, causing the disk to move in the

direction of the fluid.

The

thin layer of fluid that interacts with the disk surface in this way is called

the boundary layer, and

the interaction of the fluid with the solid surface is called the boundary

layer effect. As a result of this effect, the propelling fluid

follows a rapidly accelerated spiral path along the disk faces until it reaches

a suitable exit. Because the fluid moves in natural paths of least resistance,

free from the constraints and disruptive forces caused by vanes or blades, it

experiences gradual changes in velocity and direction. This means more energy

is delivered to the turbine. Indeed, Tesla claimed a turbine efficiency of 95

percent, far higher than other turbines.

The

Future of the Tesla Turbine

Tesla

always was a visionary. He did not see his bladeless turbine

as an end itself, but as a means to an end. His ultimate goal was to replace the

piston combustion engine with a much more efficient, more reliable engine based

on his technology. The most efficient piston combustion

engines did not get above 27 to 28 percent efficiency in their conversion of

fuel to work.

Tesla

never saw the car produced, but he might be gratified today to see that his

revolutionary turbine is finally being incorporated into a new generation of

cleaner, more efficient vehicles. One company making serious progress is

Phoenix Navigation and Guidance Inc. (PNGinc), located in Munising, Michigan

Clearly,

these stronger, more durable materials are critical if the Tesla turbine is

going to enjoy any commercial success. Had materials such as Kevlar been

available in Tesla’s lifetime, it’s quite likely that the turbine would have

seen greater use. But as was often the case with the inventor’s work, the Tesla

turbine was a machine far ahead of its time.

No comments:

Post a Comment

leave your opinion