ABSTRACT

The cam has been an integral part of the IC engine from

its invention. The cam controls the breathing channels of the IC engines, that

is, the valves through which the fuel air mixture (in SI engines) or air (in CI

engines) is supplied and exhaust driven out.

Beside

by demands for better fuel economy, more power, and less pollution, engineers

around the world are pursuing a radical camless design that promises to deliver

the internal-combustion engines biggest efficiency improvement in years. The

aim of all this effort is liberation from a constraint that has handcuffed

performance since the birth of the internal-combustion engine more than a

century ago. Camless engine technology is soon to be a reality for commercial

vehicles. In the camless valve train, the valve motion is controlled directly

by a valve actuator - there’s no camshaft or connecting mechanisms. Precise

electronic circuit controls the operation of the mechanism, thus bringing in

more flexibility and accuracy in opening and closing the valves. The seminar

looks at the working of the electronically controlled camless engine with

electro-mechanical valve actuator, its general features and benefits over

conventional engine.

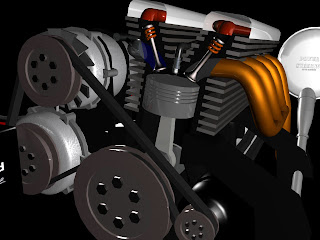

The

engines powering today’s vehicles, whether they burn gasoline or diesel fuel,

rely on a system of valves to admit fuel and air to the cylinders and to let

exhaust gases escape after combustion. Rotating camshafts with

precision-machined egg-shaped lobes, or cams they push open the valves at the

proper time and guide their closure, typically through an arrangement of

pushrods, rocker arms, and other hardware. Stiff springs return the valves to

their closed position.

INTRODUCTION

The cam has been an integral part of

the IC engine from its invention. The cam controls the “breathing channels” of

the IC engines, that is, the valves through which the fuel air mixture (in SI

engines) or air (in CI engines) is supplied and exhaust driven out. Besieged by

demands for better fuel economy, more power, and less pollution, motor engineers

around the world are pursuing a radical “camless” design that promises to

deliver the internal – combustion engine’s biggest efficiency improvement in

years. The aim of all this effort is liberation from a constraint that has

handcuffed performance since the birth of the internal-combustion engine more

than a century ago. Camless engine technology is soon to be a reality for

commercial vehicles. In the camless valve train, the valve motion is controlled

directly by a valve actuator – there’s no camshaft or connecting mechanisms

.Precise electrohydraulic camless valve train controls the valve operations,

opening, closing etc. The seminar looks at the working of the electrohydraulic

camless engine, its general features and benefits over conventional engines.

The engines

powering today’s vehicles, whether they burn gasoline or diesel fuel, rely on a

system of valves to admit fuel and air to the cylinders and let exhaust gases

escape after combustion. Rotating steel camshafts with precision-machined cams

they push open the valves at the proper time and guide their closure, typically

through an arrangement of pushrods, rocker arms, and other hardware. Stiff

springs return the valves to their closed position. In an overhead-camshaft

engine, a chain or belt driven by the crankshaft turns one or two camshafts

located atop the cylinder head. A single overhead camshaft (SOHC) design uses

one camshaft to move rockers that open both inlet and exhaust valves.

PUSH ROD

ENGINE

Pushrod engines have been installed in

cars since the dawn of the horseless carriage. A pushrod is exactly what its

name implies. It is a rod that goes from the camshaft to the top of the

cylinder head which push open the valves for the passage of fuel air mixture

and exhaust gases. Each cylinder of a pushrod engine has one arm (rocker arm)

that operates the valves to bring the fuel air mixture and another arm to

control the valve that lets exhaust gas escape after the engine fires. There

are several valve train arrangements for a pushrod.

Crankshaft:

Crankshaft

is the engine component from which the power is taken. It receives the power

from the connecting rods in the designated sequence for onward transmission to

the clutch and subsequently to the wheels. The crankshaft assembly includes the

crankshaft and bearings, the flywheel, vibration damper, sprocket or gear to

drive camshaft and oil seals at the front and rear.

Camshaft:

The

camshaft provides a means of actuating the opening and controlling the period

before closing, both for the inlet as well as the exhaust valves, it also

provides a drive for the ignition distributor and the mechanical fuel pump. The camshaft consists of a number of

cams at suitable angular positions for operating the valves at approximate

timings relative to the piston movement and in the sequence according to the

selected firing order. There are two lobes on the camshaft for each cylinder of

the engine; one to operate the intake valve and the other to operate the

exhaust valve.

Working:

When the crank shaft turn the cam

shaft the cam lobs come up under the valve lifter and cause the lifter to move

upwards. The upward push is carried by the pushrods through the rocker arm. The

rocker arm is pushed by the pushrod, the other end moves down. This pushes down

on the valve stem and cause it to move down thus opening the port. When the cam

lobe moves out from under the valve lifter, the valve spring pulls the valve

back upon its seat. At the same time stem pushes up on the rocker arm, forcing

it to rock back. This pushes the push rods and the valve lifter down, thus

closing the valve. The figure-1, shows cam-valve arrangement in conventional

engines.

Since the timing of the engine is dependent on the shape of the cam

lobes and the rotational velocity of the camshaft, engineers must make

decisions early in the automobile development process that affect the engine’s

performance. The resulting design

represents a compromise between fuel efficiency and engine power. Since maximum efficiency and maximum power

require unique timing characteristics, the cam design must compromise between

the two extremes.

This compromise is a prime consideration when consumers purchase

automobiles. Some individuals value

power and lean toward the purchase of a high performance sports car or towing

capable trucks, while others value fuel economy and vehicles that will provide

more miles per gallon.

Recognizing this

compromise, automobile manufacturers have been attempting to provide vehicles

capable of cylinder deactivation, variable valve timing (VVT), or variable

camshaft timing (VCT). These new designs

are mostly mechanical in nature.

Although they do provide an increased level of sophistication, most are

still limited to discrete valve

timing changes over a limited range.

CAMLESS ENGINES

To eliminate the cam, camshaft and other

connected mechanisms, the Camless engine makes use of three vital components –

the sensors, the electronic control unit and the actuator.

Mainly five sensors are used in connection with the valve operation.

One for sensing the speed of the engine, one for sensing the load on the

engine, exhaust gas sensor, valve position sensor and current sensor. The

sensors will send signals to the electronic control unit.

The

electronic control unit consists of a microprocessor, which is provided with a

software algorithm. The microprocessor issues signals to the solid-state

circuitry based on this algorithm, which in turn controls the actuator, to

function according to the requirements.

CAMLESS VALVE TRAIN

In

the past, electro hydraulic camless systems were created primarily as research

tools permitting quick simulation of a wide variety of cam profiles. For

example, systems with precise modulation of a hydraulic actuator position in

order to obtain a desired engine valve lift versus time characteristic, thus

simulating the output of different camshafts. In such systems the issue of

energy consumption is often unimportant. The system described here has been

conceived for use in production engines. It was, therefore, very important to

minimize the hydraulic energy consumption. The different types of valve trains

are as follows:

ELECTROMECHANICAL

POPPET VALVES

This type of system uses an armature attached to the valve stem. The

outside casing contains a magnetic coil of some sort that can be used to either

attract or repel the armature, hence opening or closing the valve.

Most early systems employed solenoid and magnetic

attraction/repulsion actuating principals using an iron or ferromagnetic

armature. These types of armatures limited the performance of the actuator

because they resulted in a variable air gap. As the air gap becomes larger (ie

when the distance between the moving and stationary magnets or electromagnets

increases), there is a reduction in the force. To maintain high forces on the

armature as the size of the air gap increases, a higher current is employed in

the coils of such devices. This increased current leads to higher energy losses

in the system, not to mention non-linear behaviour that makes it difficult to

obtain adequate performance. The result of this is that most such designs have

high seating velocities (i.e. the valves slam open and shut hard!) and the

system cannot vary the amount of valve lift.

The electromechanical valve actuators

of the latest poppet valve design eliminate the iron or ferromagnetic armature.

Instead it is replaced with a current-carrying armature coil. A magnetic field

is generated by a magnetic field generator and is directed across the fixed air

gap. An armature having a current-carrying armature coil is exposed to the

magnetic field in the air gap. When a current is passed through the armature

coil and that current is perpendicular to the magnetic field, a force is

exerted on the armature. When a current runs through the armature coil in

either direction and perpendicular to the magnetic field, an electromagnetic

vector force, known as a Lorentz force, is exerted on the armature coil. The

force generated on the armature coil drives the armature coil linearly in the

air gap in a direction parallel with the valve stem. Depending on the direction

of the current supplied to the armature coil, the valve will be driven toward

an open or closed position. These latest electromechanical valve actuators

develop higher and better-controlled forces than those designs mentioned

previously. These forces are constant along the distance of travel of the

armature because the size of the air gap does not change.

The key component of the Siemens-developed infinitely

variable electromechanical valve train is an armature-position sensor. This

sensor ensures the exact position of the armature is known to the ECU at all

times and allows the magnetic coil current to be adjusted to obtain the desired

valve motion.

Now referring within Figures 5, FIG. (1 to 4), an

electromechanical valve actuator of the poppet valve variety is illustrated in

conjunction with an intake or exhaust valve (22). The valve (22) includes a

valve closure member (28) having a cylindrical valve stem (30) and a

cylindrical valve head (32) attached to the end of the stem (30).The valve

actuator (20) of the poppet valve system generally includes a housing assembly

(34) consisting of upper and lower tubular housing members (36) and (42). A

magnetic field generator consisting of upper and lower field coils (48) and

(52), a core (56) consisting of upper and lower core member (58) and (68), and

an armature (78) suitably connected to the valve stem (30). The armature coil

is preferably made from aluminum wire or other electrically conductive

lightweight material, which is highly conductive for its mass. Minimizing the

armature mass is especially important in view of the rapid acceleration forces

placed on it in both directions.

The ability of the electromechanical valve actuator to

generate force in either direction and to vary the amount of force applied to

the armature in either direction is an important advantage of this design. For

instance, varying the value of the current through the armature coil and/or

changing the intensity of the magnetic field can control the speed of opening

and closing of the valve. This method can also be used to slow the valve

closure member to reduce the seating velocity, thereby lessening wear as well

as reducing the resulting noise.

Siemens report that a special software algorithm is used

to control the actuator coil currents such that the valves are decelerated to a

speed near zero as they land - in conjunction with a switching time of barely

three milliseconds. For the valves this means minimal wear and minimum noise

generation. The 16-valve four cylinder engine that is currently undergoing

tests in Germany, by Siemens, is equipped with 16 valve actuators and the

corresponding armature-position sensors. A Siemens ECU is used and two cable

rails connect the actuators to it. A 42-volt starter-generator provides the

power.

ELECTROMECHANICAL BALL VALVES:

An alternative to the conventional poppet valve for use

in camless valve trains is a ball valve. This type of electromechanical valve

system consists of a ball through which a passage passes. If the ball is

rotated such that the passage lines up with other openings in the valve

assembly, gas can pass through it. (Exactly like the ball valves many of us use

valve is accomplished by electromagnets positioned around its exterior to

control our boost).

Referring to Figure 6, the valve housing (7) is shown in

two pieces. Ball valve (8) has two rigidly attached pivots (12). The disc (10)

is permanently attached and indexed to the ball valve and contains permanent

magnets around its perimeter. The electromagnets (11) are situated on both

sides of the ball valve (8) and they are fixed to the valve housing. The

electromagnets are controlled through the ECU. A crank trigger sensor on the

crankshaft provides information about the position of the pistons relative to

top dead centre. Thus, at top dead centre of the power stroke, the ECM could be

used to fix the polarity of both electromagnets so that they are of opposite

polarity to the magnets in the ball valve, rotating the ball valve to the

closed position.

The substitution of a simple, efficient ball valve and

valve housing arrangement in a four stroke reciprocation piston engine

eliminates all the independent moving parts in the valve train. This may even

be an improvement over the poppet valve camless system - the ball valve needs

only to rotate on its axis to achieve the desired flow conditions, rather than

be accelerated up and down in a linear fashion. A partially open ball valve

state may also be able to be used to create more turbulence.

Electromechanical valve train implementation would not

be possible with a normal 12V electrical system. The automotive industry has

chosen a 42V electrical system as the next automotive standard. Consequently,

the energy demand of EMVT can be optimally matched by a crankshaft-mounted

starter-generator (KSG - in Siemens speak) operating at 42V; it is integrated in

the flywheel and designed for the starting process as well as generator

operation.

ELECTROHYDRAULIC POPPET VALVES:

In general terms, present designs of electrohydraulic

valves comprise poppet valves moveable between a first and second position.

Used is a source of pressurized hydraulic fluid and a hydraulic actuator

coupled to the poppet valve. The motion between a first and second position is

responsive to the flow of the pressurized hydraulic fluid. An electrically

operated hydraulic valve controls the flow of the pressurized hydraulic fluid

to the hydraulic actuator. In one design, the provision is made for a three-way

electrically operated valve to control the flow of the pressurized hydraulic

fluid to the actuator. This supplies pressure when electrically pulsed open,

and dumps actuator oil to the engine oil sump when the valve is electrically

pulsed to close. The use of engine oil as the hydraulic fluid simplifies and

lowers the cost of the design by removing the need for a separate hydraulic system.

The engine poppet valves (22) and the

valve springs (24) that are used to reset them are shown. The poppet valves are

driven by hydraulic actuators (26), which are controlled by electrically

operated electro-hydraulic valves (28) supplying hydraulic fluid to the

actuators via conduit (29). The preferred hydraulic fluid is engine oil,

supplied to the electro-hydraulic valves by the pressure rail (30). An

engine-driven hydraulic pump (32) supplies the oil pressure, receiving the oil

from the engine oil sump (34). The pump output pressure is also limited by an

unloader valve (36), as controlled by an accumulator (38) connected to the oil

pressure rail. With this design the hydraulic pump could be periodically

disconnected, such as under braking, so that the valve train would run off the

stored accumulator hydraulic pressure.

As is the trend with all modern engine systems, the

camless engine has an even greater reliance on sensors. The valve actuation and

control system typically needs a manifold pressure sensor, a manifold

temperature sensor, a mass flow sensor, a coolant temperature sensor, a

throttle position sensor, an exhaust gas sensor, a high resolution engine

position encoder, a valve/ignition timing decoder controller, injection driver

electronics, valve coil driver electronics, ignition coil driver electronics,

air idle speed control driver electronics and power down control electronics.

A valve developed by Sturman Industries is said to be

about six times faster than conventional hydraulic valves. To achieve such

speeds, it uses a tiny spool sandwiched between two electrical coils. By

passing current back and forth between the coils, a microprocessor-based

controller can quickly move the spool back and forth, thereby actuating the

engine valves in accordance.

ADVANTAGES OF CAMLESS ENGINE

Electro hydraulic camless valve train offers a

continuously variable and independent control of all aspects of valve motion.

This is a significant advancement over the conventional mechanical valve train.

It brings about a system that allows independent scheduling of valve lift,

valve open duration, and placement of the event in the engine cycle, thus

creating an engine with a totally uncompromised operation. Additionally, the

ECV system is capable of controlling the valve velocity, perform selective

valve deactivation, and vary the activation frequency. It also offers

advantages in packaging. Freedom to optimize all parameters of valve motion for

each engine operating condition without compromise is expected to result in

better fuel economy, higher torque and power, improved idle stability, lower

exhaust emissions and a number of other benefits and possibilities.

Camless engines have a number of advantages over

conventional engines.

• In a

conventional engine, the camshaft controls intake and exhaust valves. Valve

timing, valve lift, and event duration are all fixed values specific to the

camshaft design. The cams always open and close the valves at the same precise

moment in each cylinder’s constantly repeated cycle of fuel-air intake,

compression, combustion, and exhaust. They do so regardless of whether the

engine is idling or spinning at maximum rpm. As a result, engine designers can

achieve optimum performance at only one speed. Thus, the camshaft limits engine

performance in that timing, lift, and duration cannot be varied.

• The

improvement in the speed of operation valve actuation and control system can be

readily appreciated with reference to Figure 9. It shows a comparison between

valve speeds of a mechanical camshaft engine and the camless engine valve

actuation. The length of the valve stroke in inches versus degrees of rotation

of a mechanical camshaft is illustrated.

When graphed, the cycle of opening and closing of a

valve driven by a mechanical camshaft will display a shape similar to a sine

curve. The opening period (as measured in crankshaft degrees) remains constant

for any engine load or rpm. However, the cycle of opening and closing of valves

driven by the electromechanical valve actuators operates much faster. Designed

to match valve-opening rate at the maximum engine rpm, the electromechanical

valve actuators open the valve at this same rate regardless of engine operating

conditions. Because of this improved speed, greater flexibility in programming

valve events is possible, allowing for improved low-end torque, lower emissions

and improved fuel economy. The massive opening period for the

electromechanically driven valve can also be seen.

But in a cam less engine, any engine valve can be opened

at anytime to any lift position and held for any duration, optimizing engine

performance. The valve timing and lift is controlled 100 percent by a

microprocessor, which means lift and duration can be changed almost infinitely

to suit changing loads and driving conditions. The promise is less pollution,

better fuel economy and performance.

• Another

potential benefit is the cam less engine’s fuel savings. Compared to

conventional ones, the cam less design can provide a fuel economy of almost

7-10% by proper and efficient controlling of the valve lifting and valve

timing.

• The

implementation of camless design will result in considerable reduction in the

engine size and weight. This is achieved by the elimination of conventional

camshafts, cams and other mechanical linkages. The elimination of the conventional

camshafts, cams and other mechanical linkages in the camless design will result

in increased power output.

• The

better breathing that a camless valve train promotes at low engine speeds can

yield 10% to 15% more torque. Camless engines can slash nitrogen oxide, or NOx,

pollution by about 30% by trapping some of the exhaust gases in the cylinders

before they can escape. Substantially reduced exhaust gas HC emissions during

cold start and warm-up operation.

CONCLUSIONS

1. An electro

hydraulic camless valve train was developed for a camless engine. Initial

development confirmed its functional ability to control the valve timing, lift,

velocity, and event duration, as well as to perform selectively variable

deactivation in a four-valve multicylinder engine.

2. Review of the benefits expected from a camless engine

points to substantial improvements in performance, fuel economy, and emissions

over and above what is achievable in engines with camshaft-based valve trains.

3. The

development of a camless engine with an electro hydraulic valve train described

in this report is only a first step towards a complete engine optimization.

Further research and development are needed to take full advantage of this

system exceptional flexibility.

No comments:

Post a Comment

leave your opinion